Oregon

Fabrication and Design

Oregon's one-stop shop for technical consultation, design, fabrication, and assembly.

Streamlined Manufacturing

Design

Start your project with us from a back-of-the-napkin sketch or an engineering drawing, and we will create CAD models with an intact feature tree. We also assist in adding the required tolerances for your end-manufacturing process, whether it's 3D printing or machining.

Consultations

Need technical advice? Missing a component? We can assist with finding parts or offer problem-solving approaches from a different angle.

Manufacture

Whether your parts are a few nanometers or a few meters, we house a wide variety of additive manufacturing (3D printing) and subtractive fabrication equipment at the OFAD labs to turn your projects to reality.

Validate

Have peace of mind for your products with our X-ray material characterization equipment that provides percentages of alloys present in your products. We also have access to high-resolution electron microscopy and microanalysis equipment through our partnering labs at the university.

The OFAD Advantage

Students are at the core of our mission.

Accomplishing a greater goal. Your projects and our resources provide experiential learning opportunities for our student employees.

Project Research

Most projects that run through OFAD labs require investigation into the desired outcome of the product that will be fabricated or printed. This approach enables our students to gain research experience and acquire knowledge of tools and their uses.

Design and CAD Modeling

Students work with faculty to design your desired CAD model using Fusion 360. Students are trained to keep all feature trees intact while maintaining a revisions history for design changes.

CAD Slicing and CAM Setup

Students are trained to perform CAM tool path planning using Fusion 360. Students are also trained in 3D print software such as PreForm.

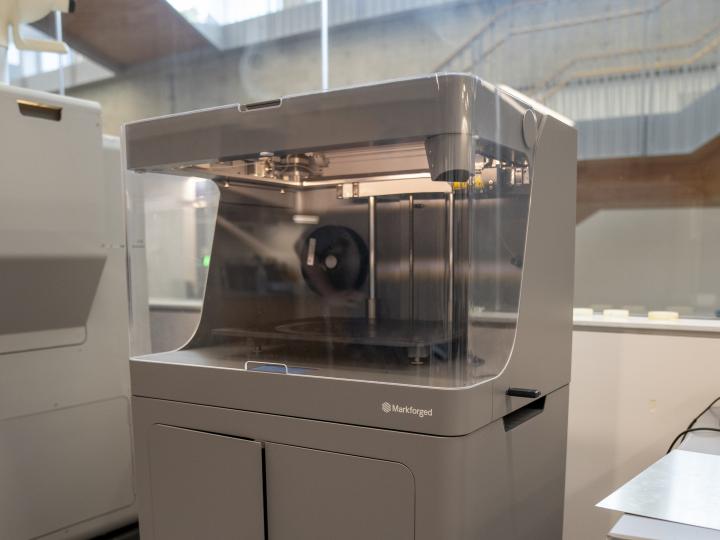

3D Printing

We have Formlabs printers and a Markforged printer available for use and training. Staff can provide the ideal material and post-processing techniques for your project.

Fabrication

Application-specific machine, material, tool, torque, passes, and other aspects of machining are taught to students.

Quality Inspection and Validation

Whether with calipers, micrometers, or 3D scanners, the importance of quality assurance for products made through OFAD labs is taught and implemented as a standard protocol for all projects.

Interested in Training?

University of Oregon faculty, staff, and students are welcome to request training in equipment available at the OFAD labs.

Resource Portfolio

Fabrication

Additive Manufacturing