Hero Envelope Title

Hero Envelope Text

About Us

Why we do what we do?

Core values | Educate, Enhance, Empower

OFAD leverages its unique position in an educational setting to provide experiential learning opportunities to students.

Product development projects in OFAD labs fuel experiential learning opportunities for students. Students have access to every step of the manufacturing process, which will enable them to gain technical and project management skills.

Value Package

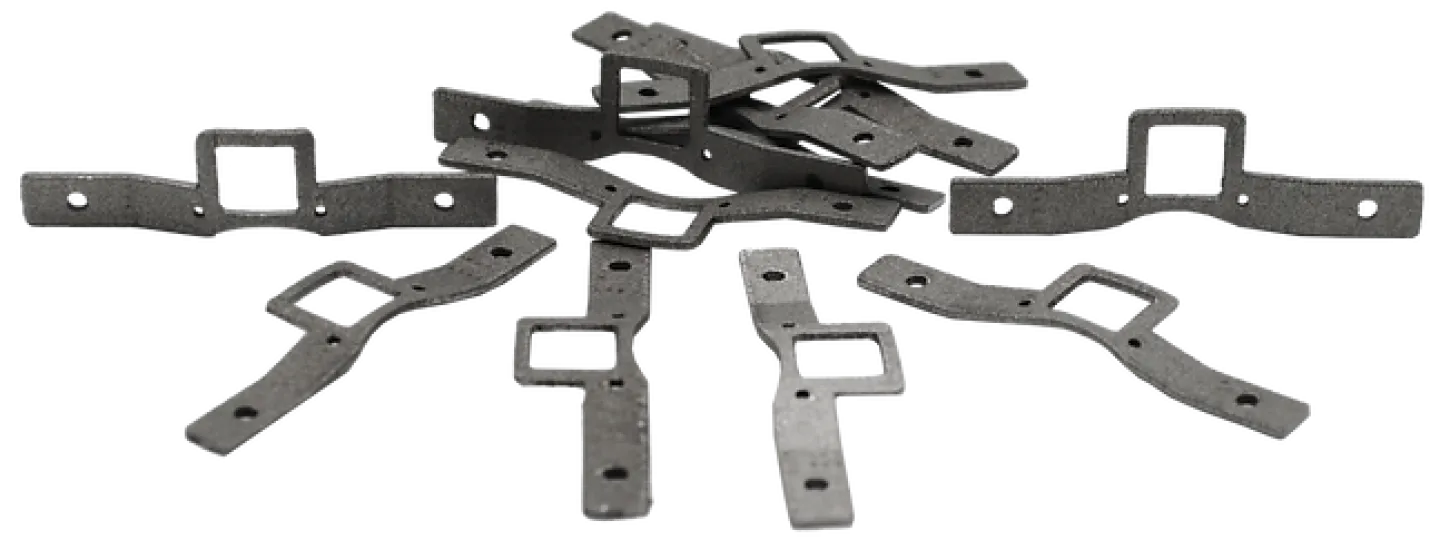

All processes in house. The centralization of fabrication and 3D printing labs within the OFAD core facility allows us to utilize the advantages of both technologies as needed. Validating materials and part quality is key for certain manufacturing projects. OFAD has access to an X-ray material/alloy characterization tool and a non-contact laser scanner for quality inspection of manufactured parts. If projects require advanced analysis, OFAD is housed at the Phil and Penny Knight Campus for Accelerating Scientific Impact with access to shared resources including as a scanning electron microscope (SEM) and sub-micron-level imaging microscopes.

OFAD Team

Nick Liebrecht

Instrument Machinist | nliebrec@uoregon.edu

Nick earned his bachelor's in chemistry from the University of Wisconsin-Whitewater in 2003 and his master's in chemistry from the University of Oregon in 2005. He has worked in the semiconductor, LED lighting, and manufacturing industries in engineering and leadership roles.

Jeffrey Garman

Legacy Machine Shop Manager | jgarman@uoregon.edu

Jeffrey Garman has been an instrument machinist at the University of Oregon since 2004.

Julian McAdams

Assistant Director of Fabrication & Design | jmcadams@uoregon.edu

Julian attended Georgia Tech and received a bachelor's (2010) and master's (2017) degrees in earth and atmospheric sciences. He worked at Georgia Tech as a research scientist and lab manager from 2012 to 2018. There he fabricated equipment, completed field research, and managed lab spaces. In 2018 he and his wife, Mary, moved to Oregon to continue work as a research scientist and a machinist with OFAD. Julian has expertise in CAD/CAM/CNC as well of the many manual machines that exist on campus.

Yun Craddock

Student Shop Assistant | ymc@uoregon.edu

Yun is an undergraduate student at the University of Oregon, pursuing a neuroscience degree.