Fabrication

Process: High-speed milling

Specialty: 60,000 RPM spindle

Work Area: 40” x 32” X, Y travel

Accuracy: 10 μm positional accuracy

Process: High-speed milling

Specialty: 40,000 RPM spindle

Work Area: 19.5″ x 15.5″ X, Y travel

Accuracy: 10 μm positional accuracy

Process: Multi-axis laser cutting

Specialty: 150 W laser

Work Area: 400 x 500 mm X, Y travel

Accuracy: +/- 2 μm positional accuracy

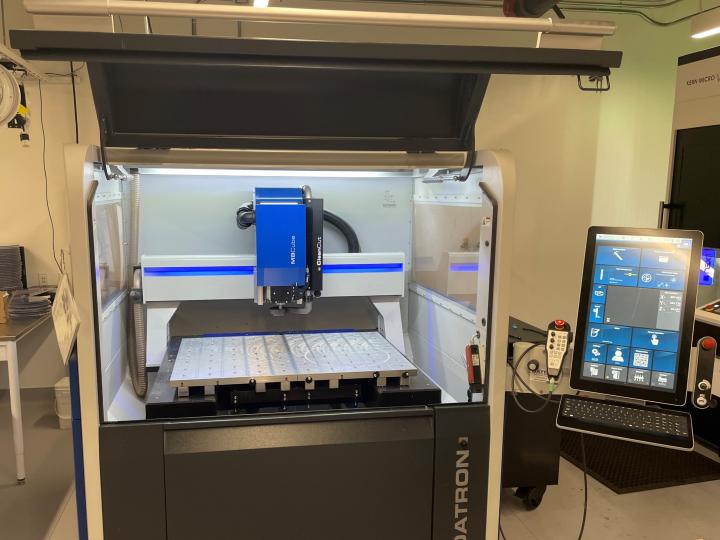

Process: 5-axis milling

Specialty: 210 tools and 60 workpieces

Work Area: 350 mm (ø) x 200 mm

Accuracy: +/- 1 μm positional accuracy

Process: 5-axis water jet cutting

Specialty: 60,000 psi linear intensifier pump

Work Area: 1981 x 3048 x 304 mm

Accuracy: +/- 100 μm linear straightness

Process: Electric discharge machining

Specialty: Sub-micron resolution

Work Area: 220 x 160 x 100 mm travel

Accuracy: 20 μm min wire capability

Extra costs applied

Process: Laser micro-welding

Specialty: 80J peak power

Work Area: 305 x 229 x 10 mm

Accuracy: 100 μm minimum weld bead

Process: Computerized numerical control

Specialty: 1800 RPM spindle

Work Area: 406 x 762 mm

Accuracy: 10 μm positional accuracy

Process: Computerized numerical control

Specialty: 8100 RPM Spindle

Work Area: 30" x 16" x 20 "

Accuracy: +/-0.002"

Additive Manufacturing

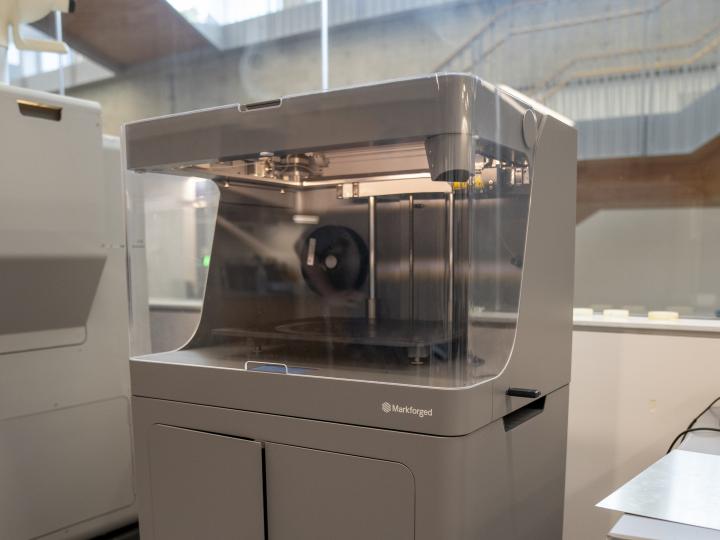

Process: Fused fabrication modeling

Material: Composite thermoplastics

Work Area: 330 x 270 x 220 mm

Accuracy: 50 μm - 250 μm

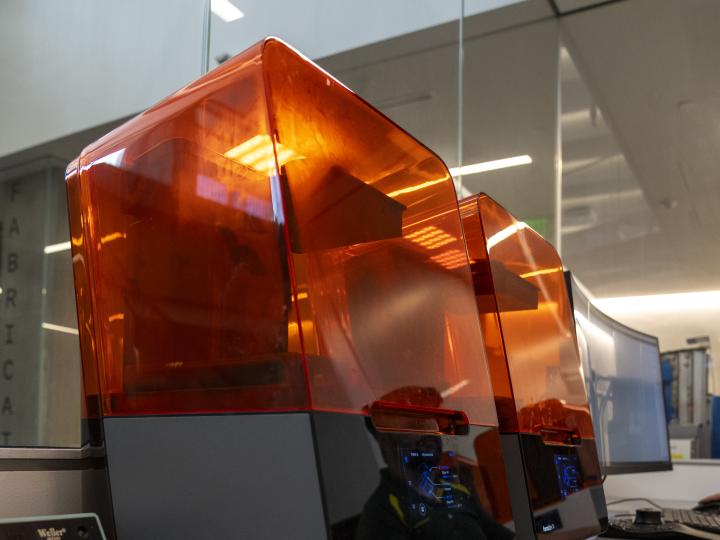

Process: Stereolithography

Material: Resin

Work Area: 145 x 145 x 185 mm

Accuracy: 25 μm

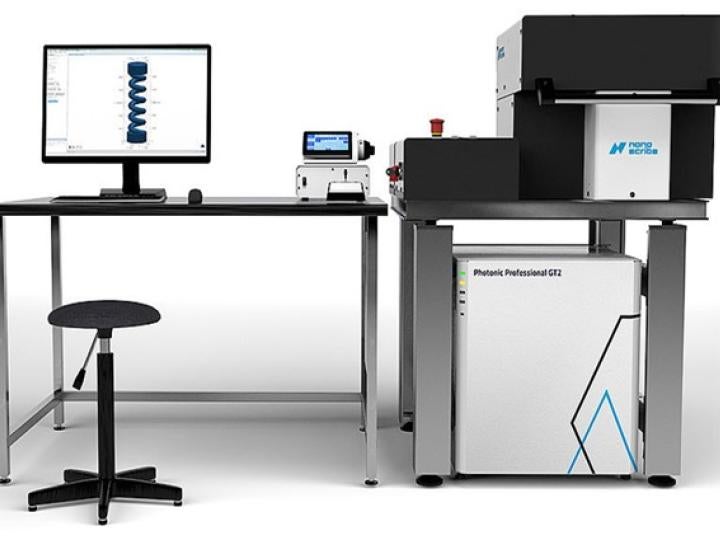

Process: Two-photon polymerization

Material: IP Resin

Work Area: 100 x 100 x 8 mm

Accuracy: 0.1 - 5.0 μm

Process: Selective laser sintering

Material: Thermoplastic nylon

Work Area: 165 x 165 x 300 mm

Accuracy: 110 μm